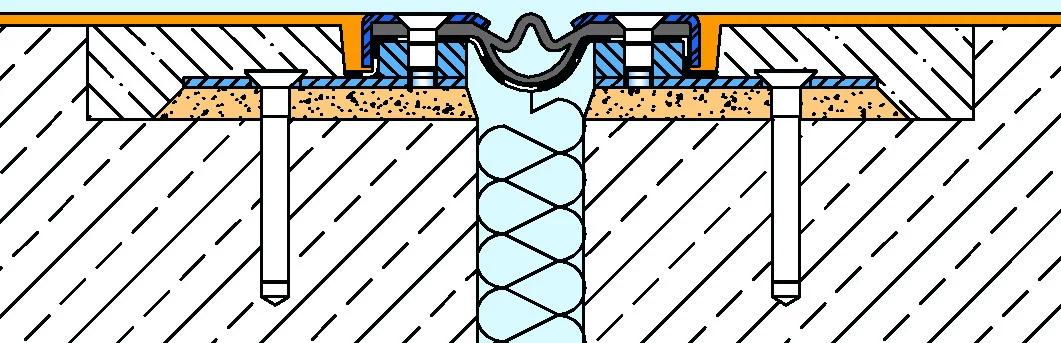

Processing instructions with coating

System example: VA.8.95/20 with grouting profile VP5/20

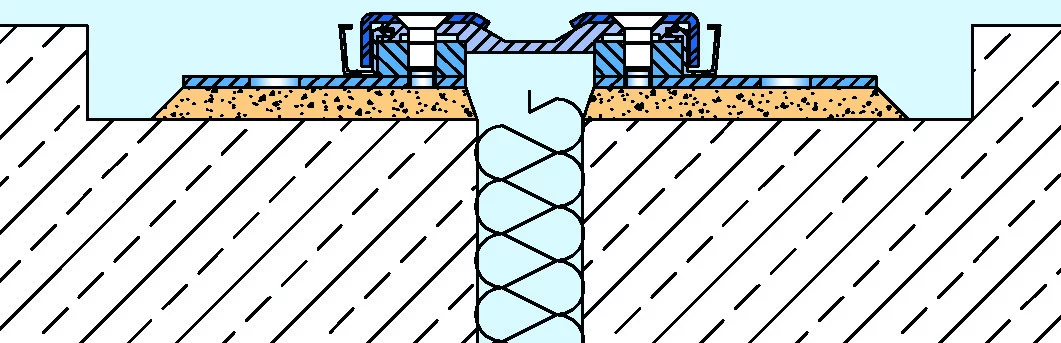

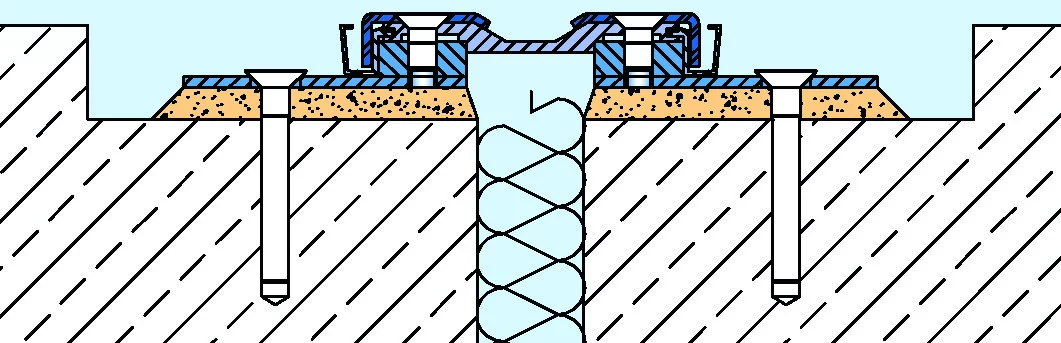

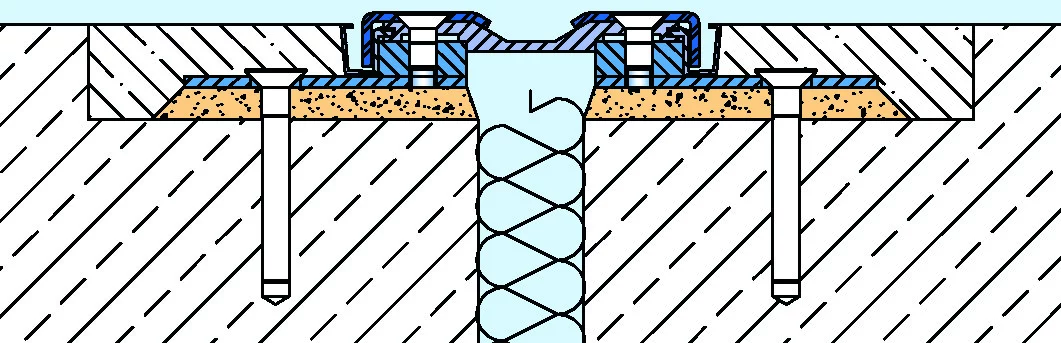

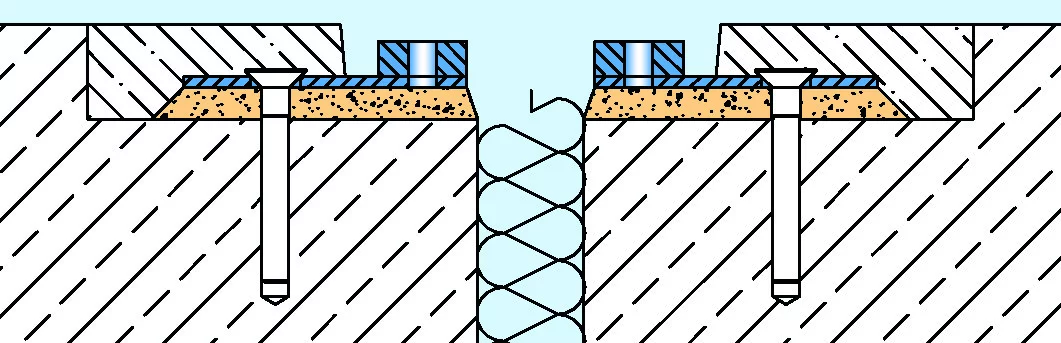

4. After the smooth coat has hardened, the joint profile is dowelled using approved fixing anchors at intervals of approx. 300 mm.

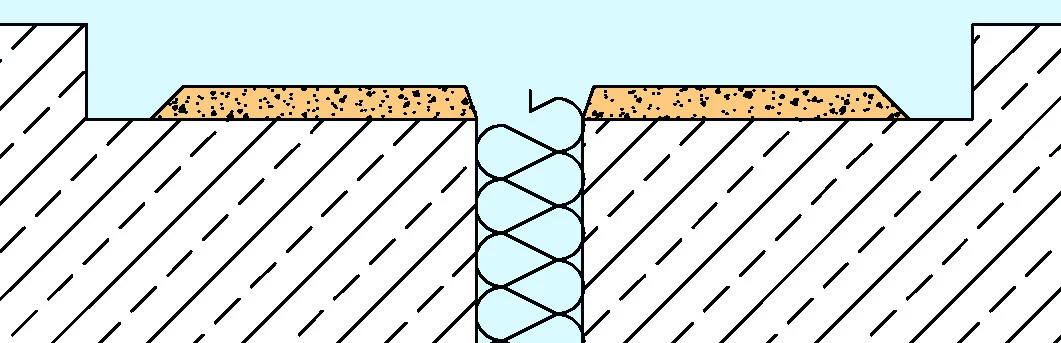

5. Filling and pulling off the mounting recess flush with the floor with a pressure-resistant and shrinkage-free epoxy resin mortar.

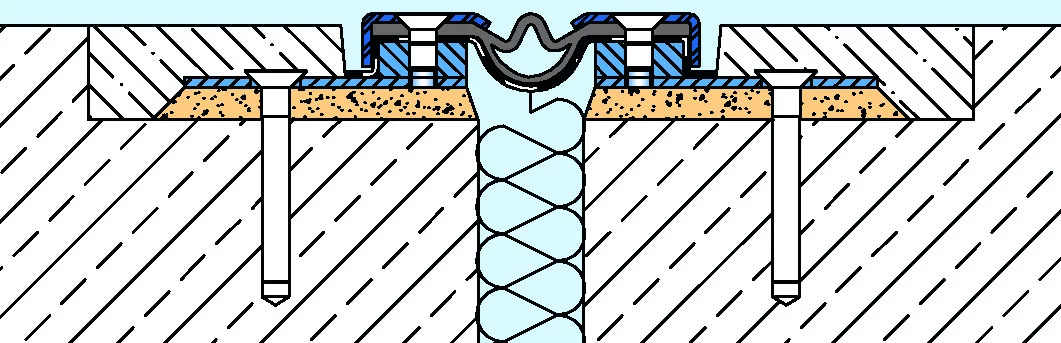

7. Insert the sealing membrane (Wolfin) as well as the expansion insert and grout using stainless steel cover caps and countersunk screw M8 at a interval of 150 mm.