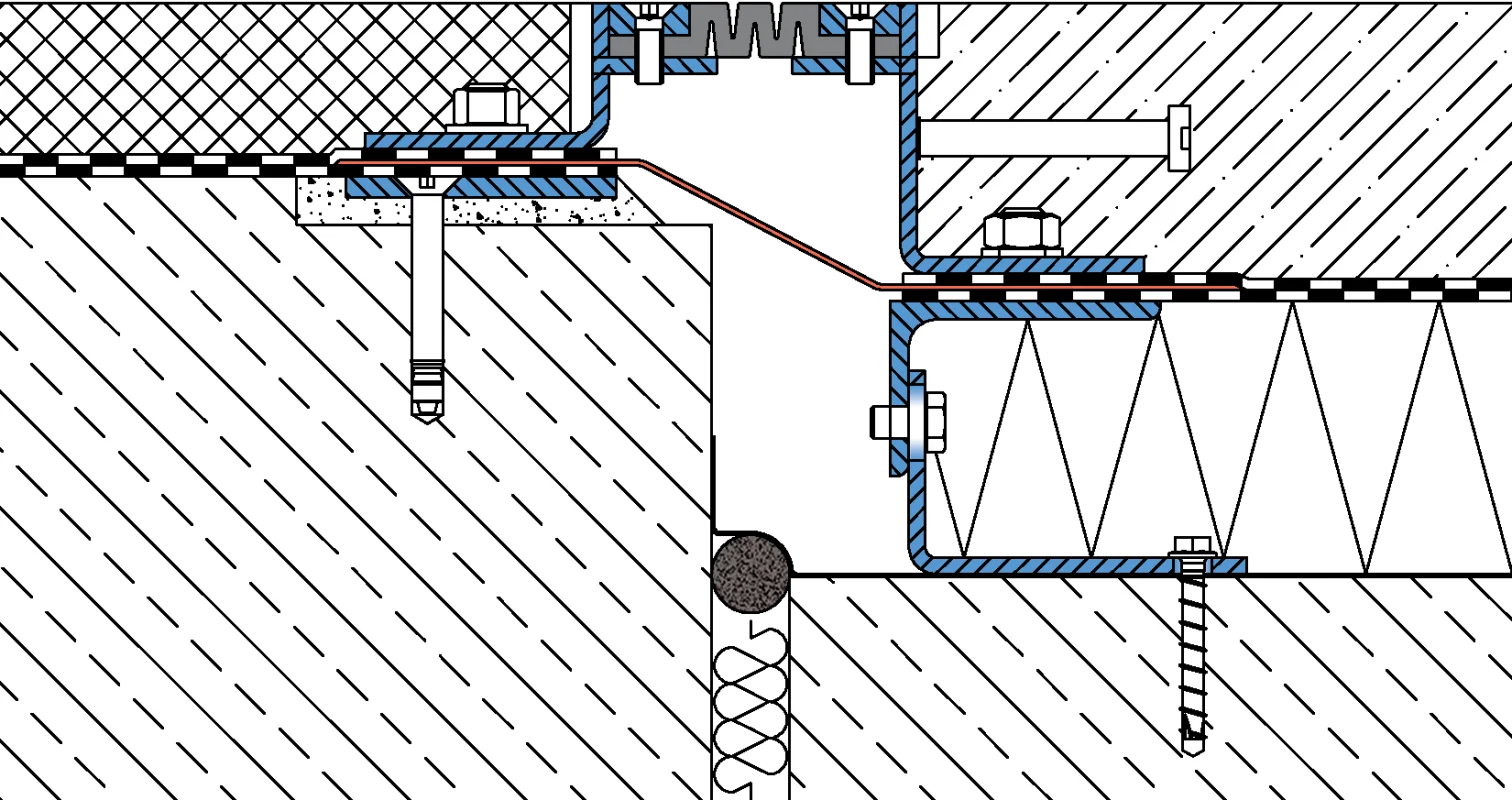

Mounting options - watertight joint profiles

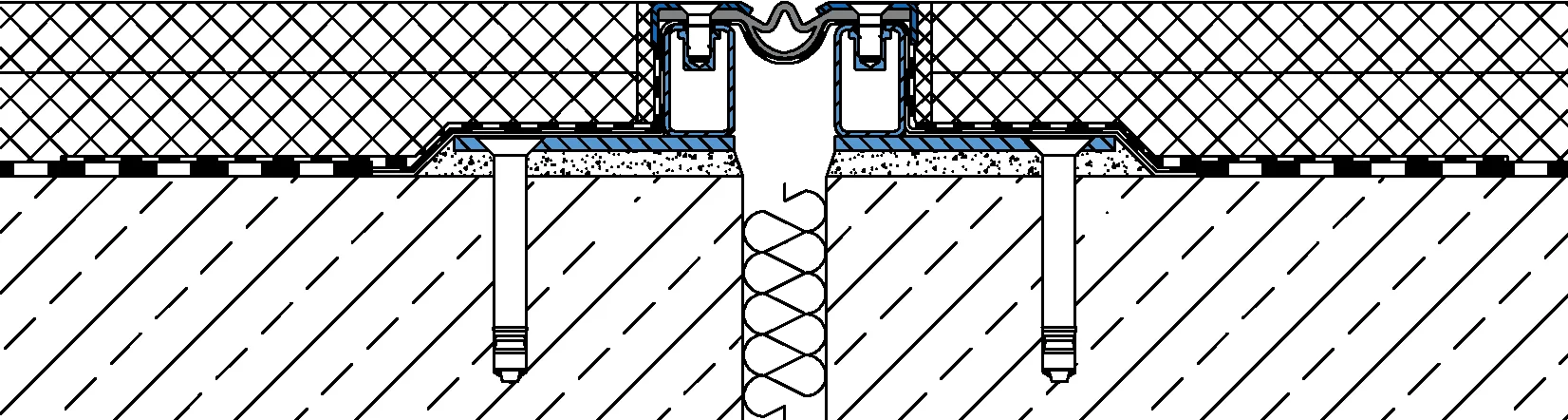

Covering change

from coating to surface sealing with asphalt covering.

System example: VA.8.95/20 combined with VA.8.95/52 F

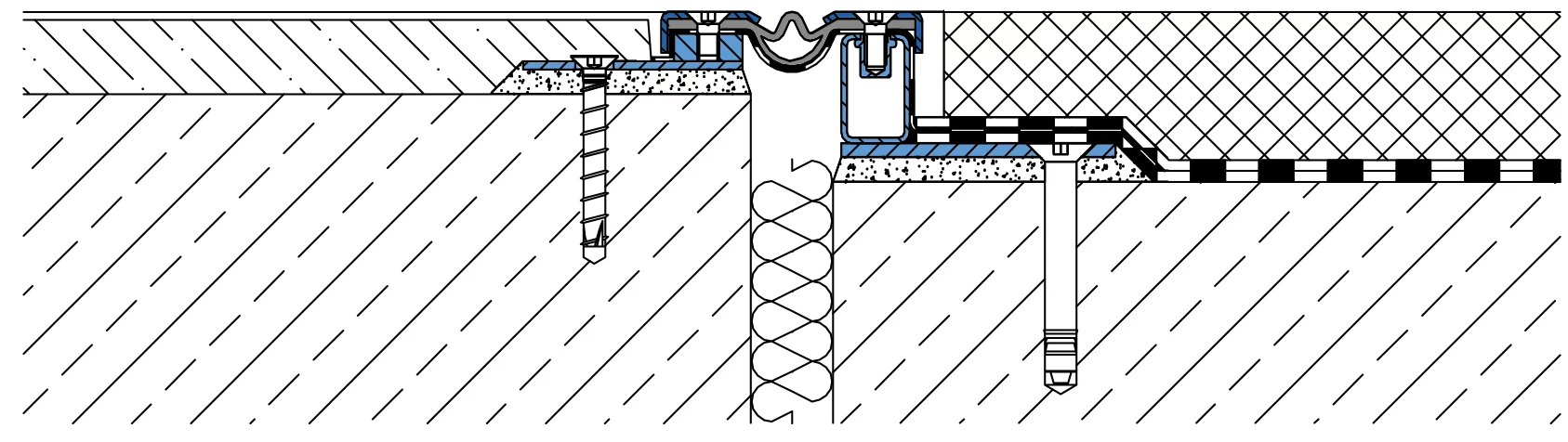

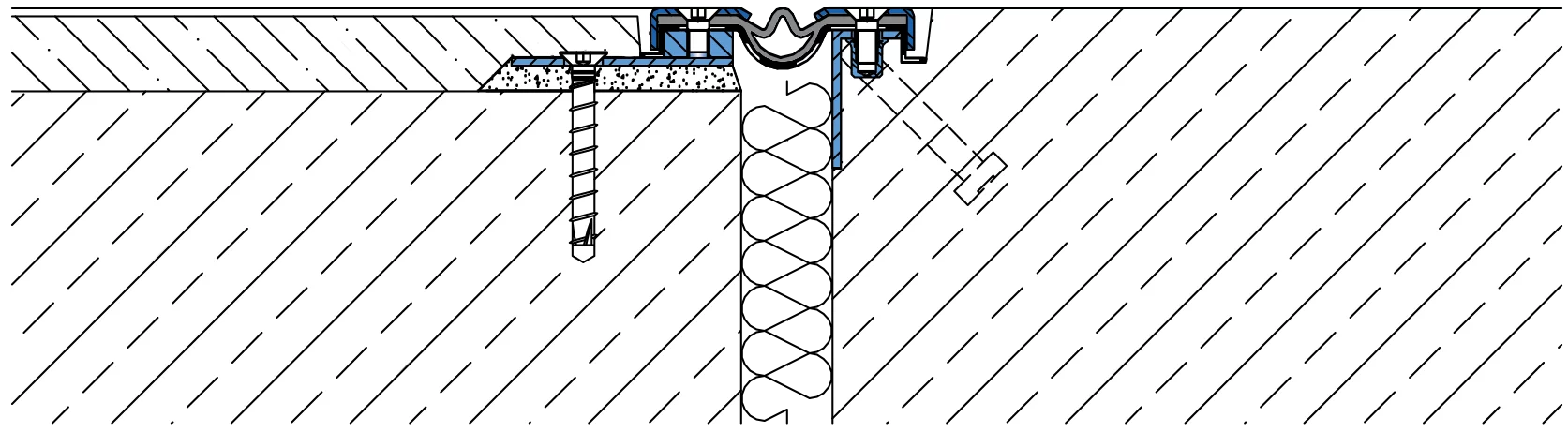

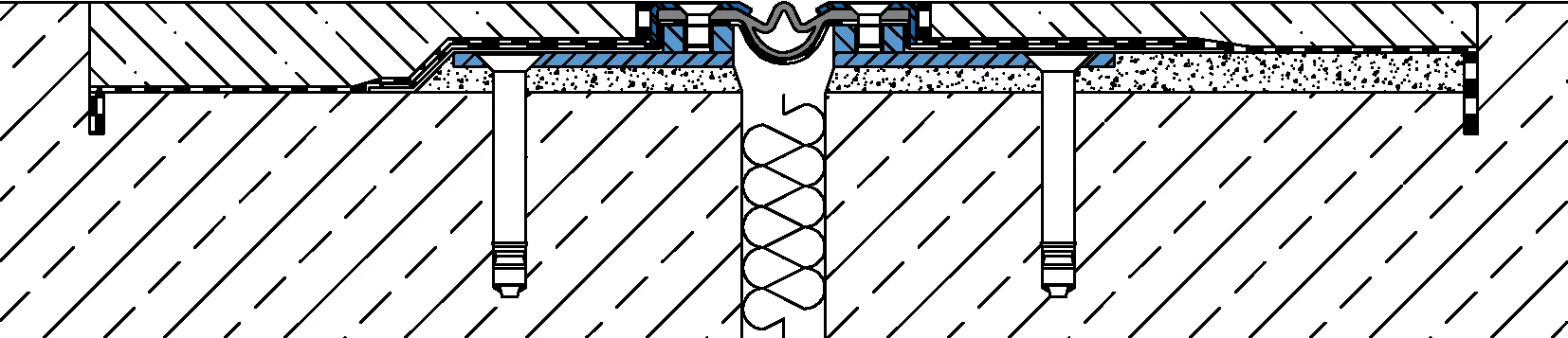

Covering change

from coating to installation in in-situ concrete.

System example: VA.8.95/20 combined with VA.8.95/0

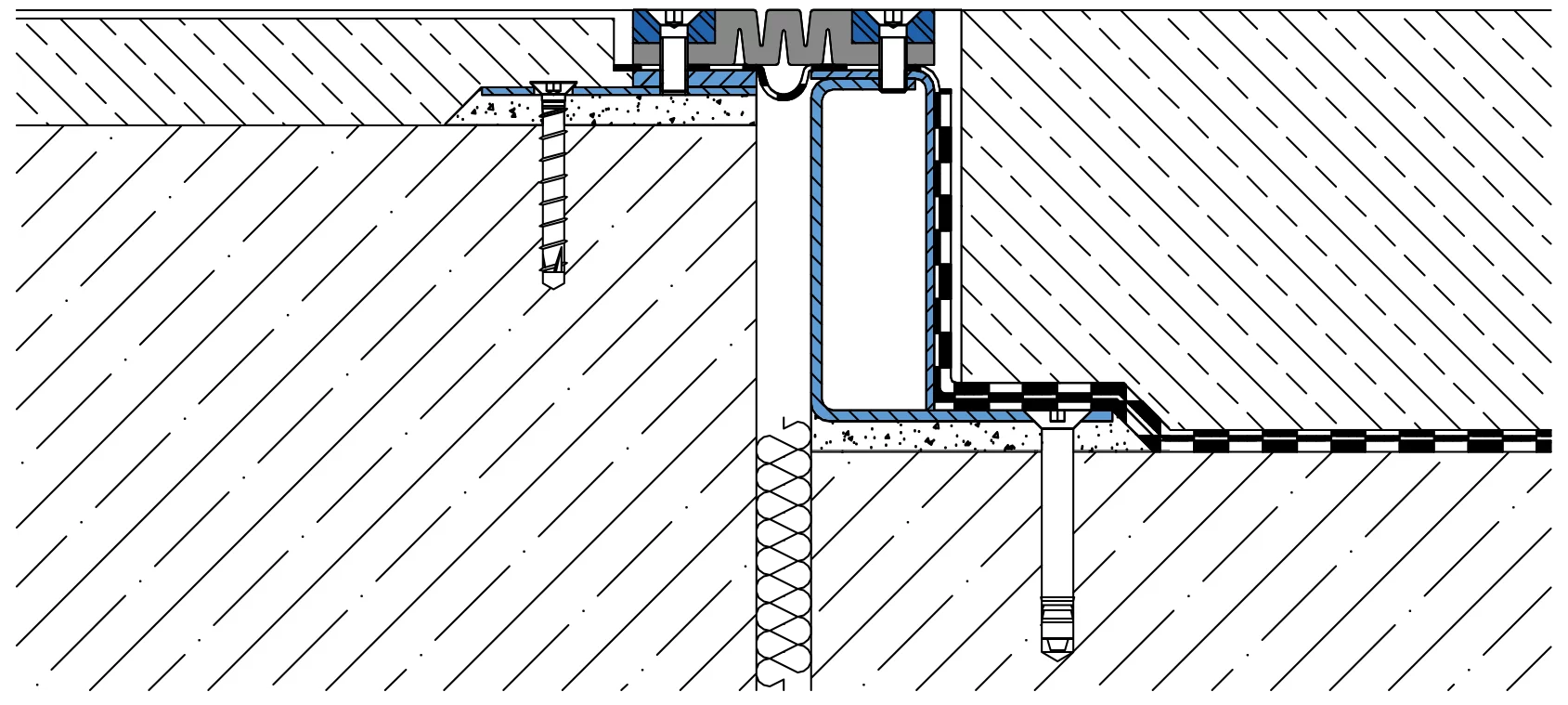

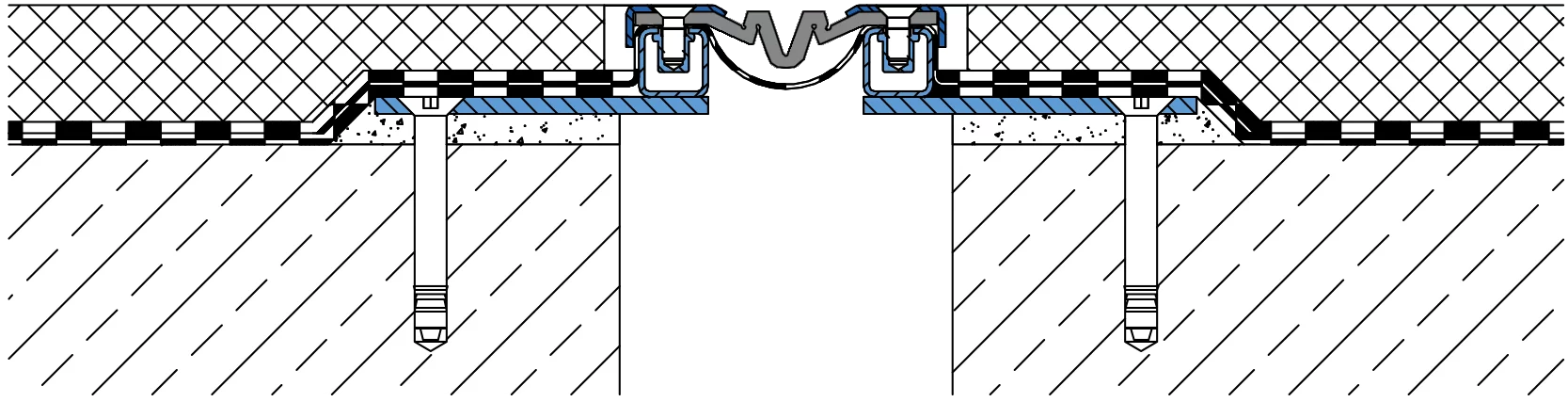

Covering change

from coating to surface sealing with screed or concrete covering.

System example: VA.8.110/30 combined with VA.8.110/150 F

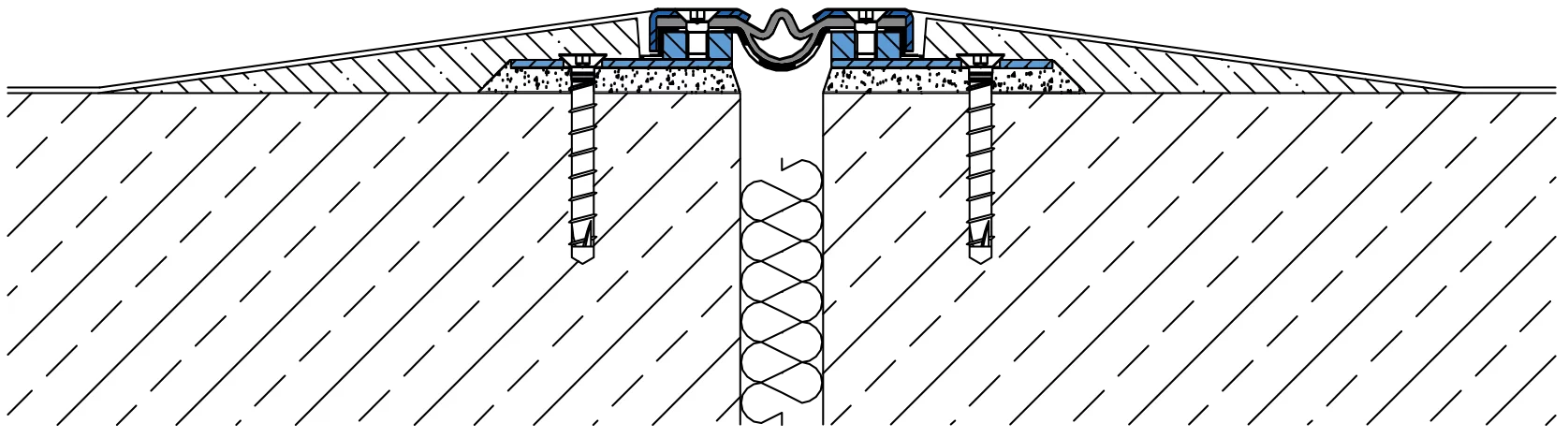

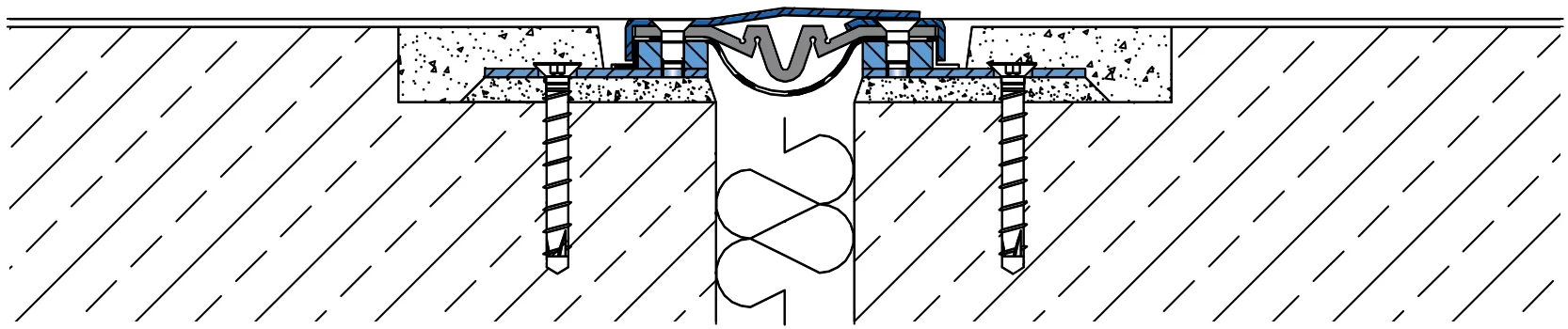

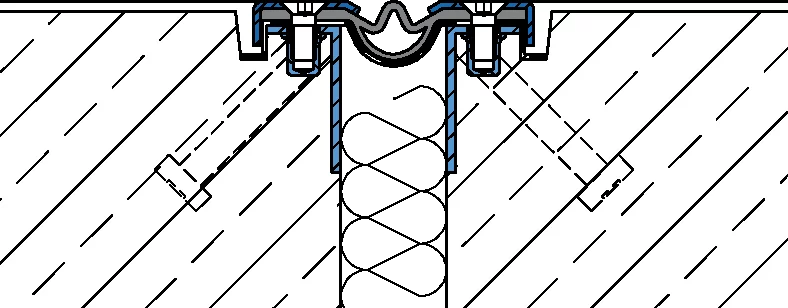

Coating

Mounted directly on the raw ceiling, suitable for renovations due to the low profile height of 21 mm.

System example: VA.8.95/20

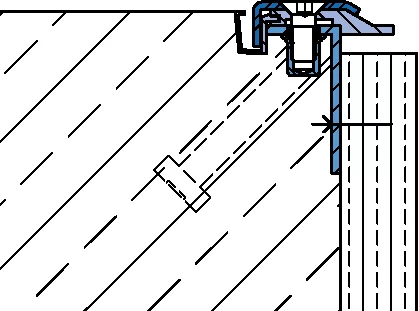

Liquid plastic

Mounted in recess, suitable for renovation without surface sealing.

System example: VA.8.95/22 F

Liquid plastic

Mounted on bare slab, suitable for surface sealing with asphalt covering during renovation.

System example: VA.8.95/52 F

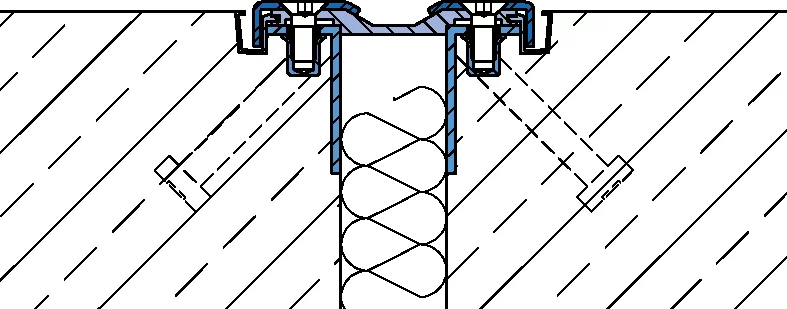

Dragging

of the fixing legs for bridging extremely wide structural joints.

System example: S-VA.8.115/37 F

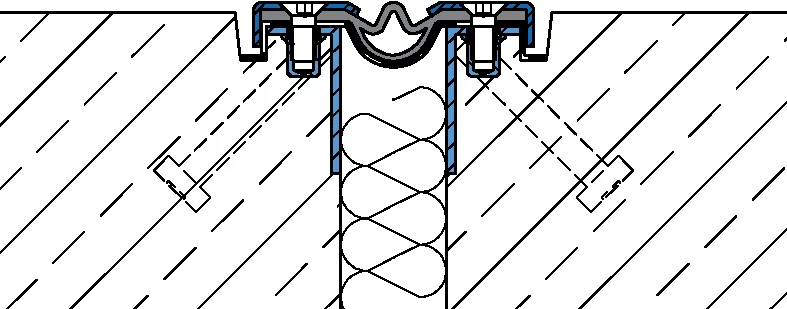

Cover plate

Top cover plate, thus no more vertical movements (settling) possible.

System example: S-VA.8.115/20

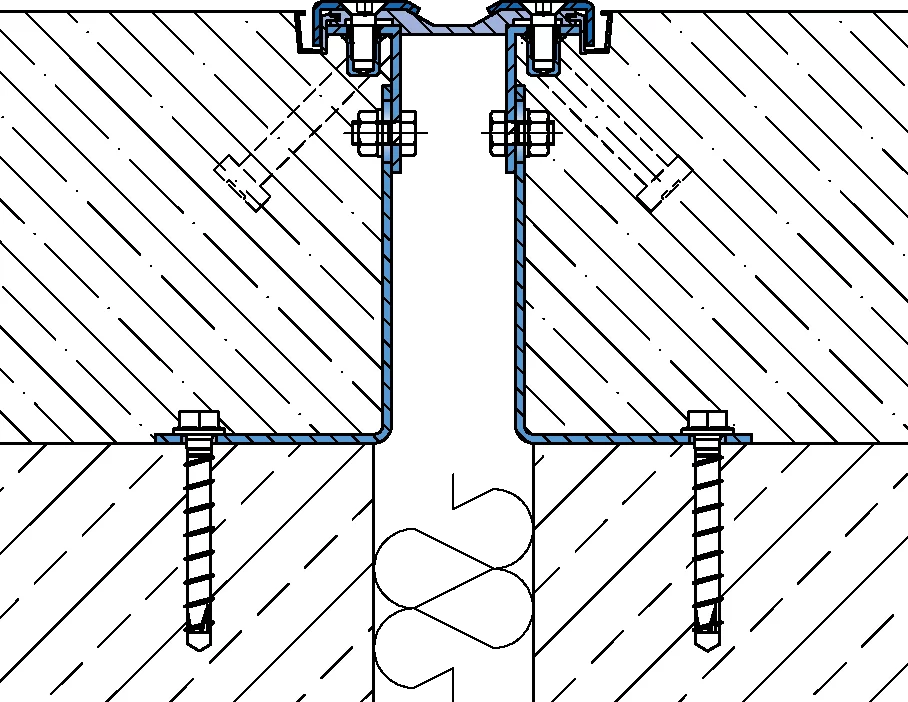

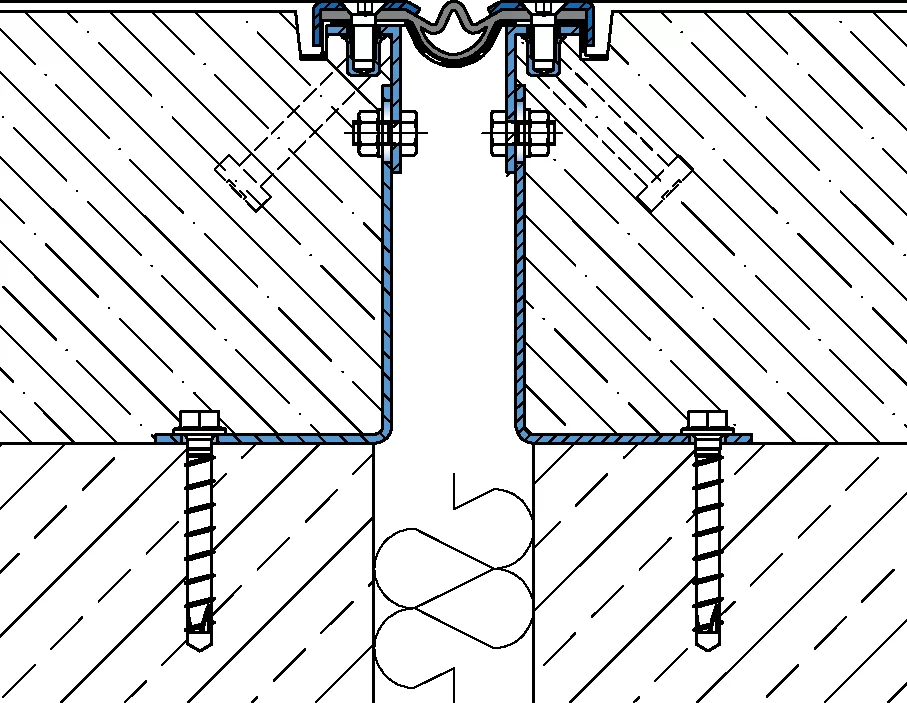

Installation on formwork

System example: VA.8.95/0 with grouting profile VP5/20

3. Before applying the coating, remove the spacer and the grouting profile VP5/20. Install the sealing membrane (Wolfin) as well as the expansion insert and press in place using stainless steel cover caps and countersunk screw M8 at 150 mm intervals.

Installation on filigree plate

System example: VA.8.95/0 with grouting profile VP5/20