Features

watertight, resistant to heavy loads, trafficable by fork-lift trucks, expansion insert can be replaced anytime, abrasion-, weather- and temperature-resistant (-40°C to +120°C), resistant to de-icing salt and waste water (alkalis, microbes, bacteria)

Applications

all industrial applications, areas with increased hygiene standards (e.g. kitchens, hospitals etc.)

Material

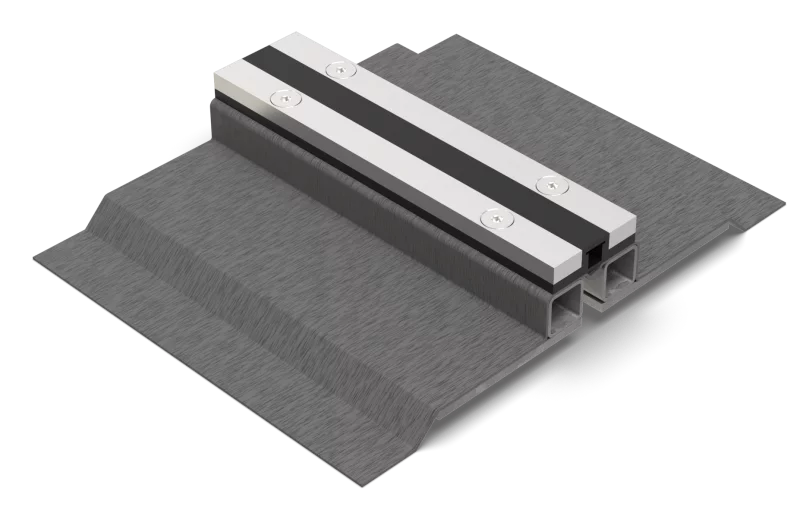

substructure hot-dip galvanised steel and visible surface stainless steel V2A (V4A on request), EPDM expansion insert, Wolfin IB sealing membrane

Covering Types

asphalt, screed, natural and stone slabs, bitumen welding membrane, liquid plastic

trafficability

passenger cars, trucks, fork-lifts

Formed parts

corner piece, T-piece, cross piece, floor-wall connections, upstand, membrane upstand

Notes

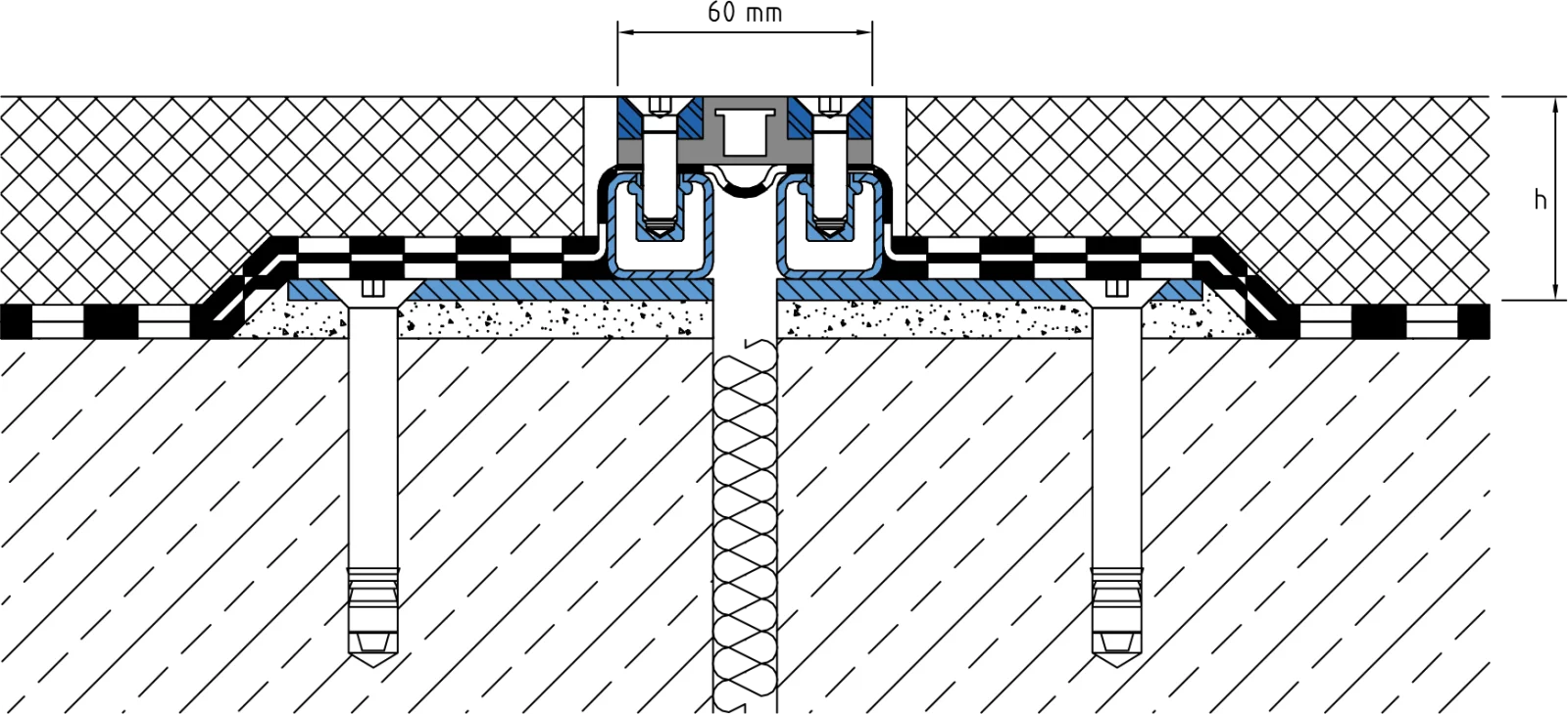

The sealing and expansion insert is flanged with screws M8 at intervals of 150 mm.

The sealing membrane projecting from the joint profile must be integrated into the sealing system to prevent water infiltration from the sides.

Installation by our own fitters recommended.